- Marketleader in no-man-entry robots

- Game-changing cleaning method

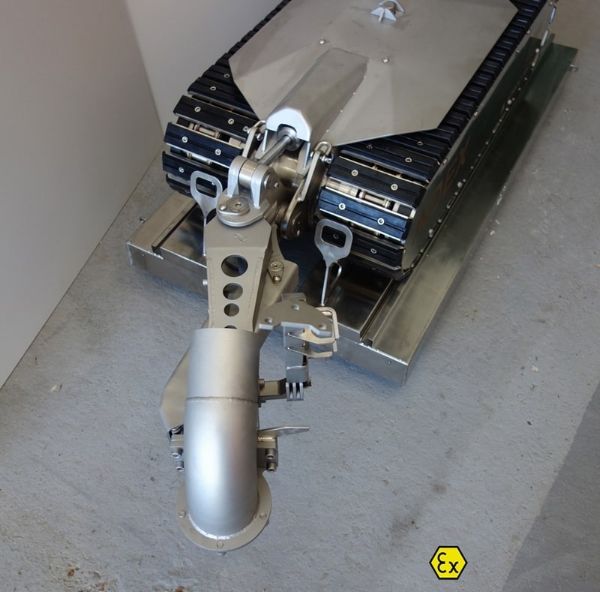

- ATEX zone 0 certified robots

The KOKS robot systems are especially designed for ATEX zone 0

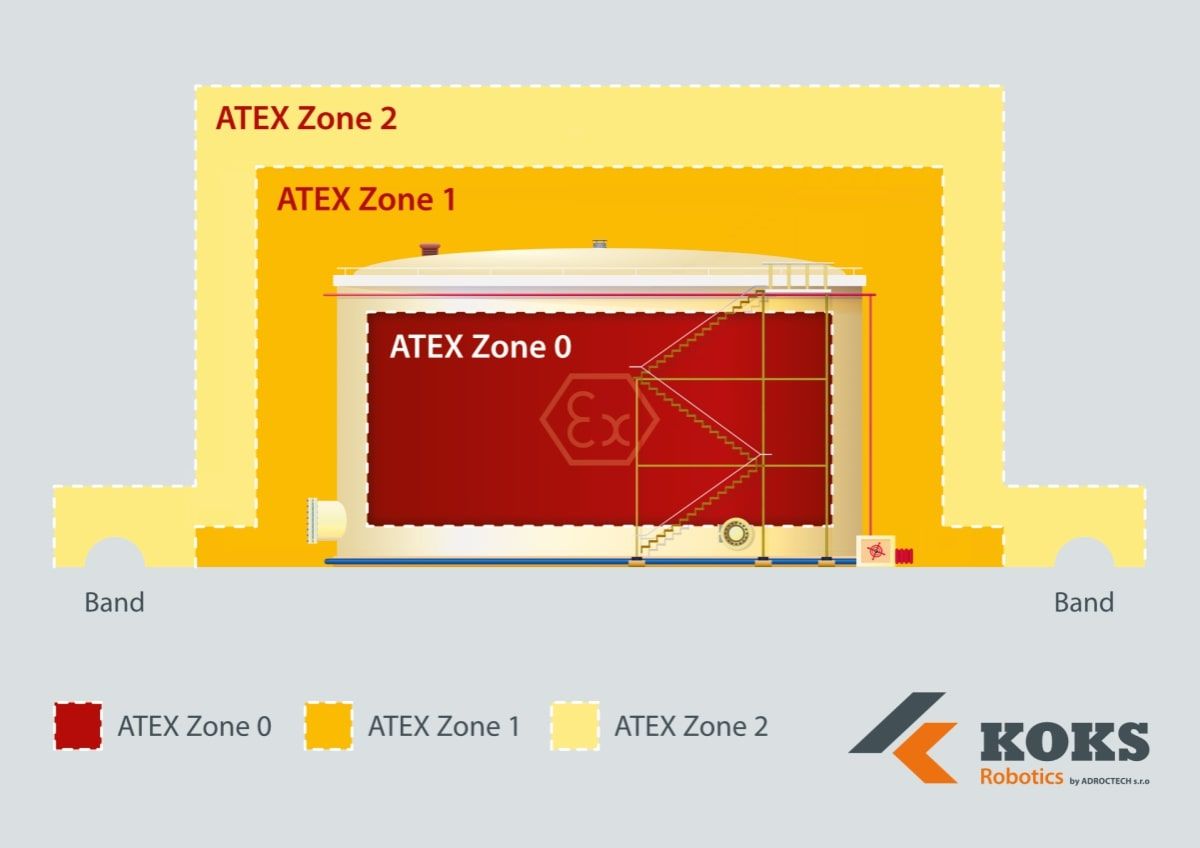

ATEX zones

The robot in the KOKS ESOT system is especially designed for the ATEX Zone 0 (zero). But which ATEX Zones are applicable? Why are there ATEX Zones and what are the definitions?

Let us start with the first acronym ATEX, this comes from the French designation ATmosphères EXplosibles and is used for two European guidelines for the explosive danger in atmospheric conditions.

First European guideline is ATEX 153, which obligate the owners to identify the ATEX zones in areas which have explosive sources. This zone division must be included in the explosion protection document.

The explosion risk is determined on the basis of a risk inventory and evaluation. Seamlessly we go over to the ATEX 114 Guideline. This guideline specifies the approved equipment per category, specifies in which zones these can be used, to prevent the equipment to create an ignition.

Explosive atmospheres (Gases, Vapours, Mist & Dusts)

How do we identify an ATEX area?

An ATEX area is defined by the probability that an explosion could occur.

Explosive atmospheres can arise because of combustible gasses, vapor, mist or dust. When there is sufficient of this, mixed with atmosphere (oxygen) and an ignition source can cause an explosion. The explosive danger can express in the following forms:

- Gas explosion

- Mist explosion

- Dust explosion

The ATEX zones for gas or mist explosive risk are indicated with ATEX zone 0, 1 or 2.

The ATEX zones for dust explosive risk are indicated with zone ATEX 20, 21, 22.

In order to define the ATEX zones the following aspects need to be considered:

- Hazardous sources, all points where gas, damp or dust could possible break out need to be documented

- The quantities of gas, vapor and dust that can be released in the are calculated

- The probability is calculated that a dangerous explosive mixture is present.

Gas, Vapours & Mist - ATEX Zones 0, 1 & 2

We start off with the gas and/or mist explosive risks zones which are indicated with ATEX Zones 0, 1 & 2.

ATEX Zone 0 (zero)

A place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is present continuously or for long periods or frequently.

An indication during normal circumstances there is high risk of explosion:

- More than 1.000 hours per year.

- >10% of the operation hours

ATEX Zone 1

A place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally.

An indication during normal circumstances there is medium risk of explosion:

- Between 10 and 1.000 hours per year.

- Between 0,1% and 10% of the operation hours

ATEX Zone 2

A place in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

An indication during normal circumstances of there is low risk of explosion:

- Less than 10 hours per year.

- <0,1% the operation hours

Dusts - ATEX Zones 20, 21 & 22

We continue with the dust explosive risks zones which are indicated with ATEX Zones 20, 21 & 22.

ATEX Zone 20

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, or for long periods or frequently.

An indication during normal circumstances there is high risk of explosion:

- More than 1.000 hours per year.

- >10% of the operation hours

ATEX Zone 21

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally.

An indication during normal circumstances there is medium risk of explosion:

- Between 10 and 1.000 hours per year.

- Between 0,1% and 10% of the operation hours

ATEX Zone 22

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

An indication during normal circumstances of there is low risk of explosion:

- Less than 10 hours per year.

- <0,1% the operation hours

KOKS Robotics is market leader and manufacturer of innovative no-man-entry tank cleaning robotics for ATEX zone 0. KOKS Robotics is part of the Dutch company KOKS Group an international manufacturer and supplier of vacuum trucks and heavy industrial cleaning equipment, built in accordance with the latest PED, ADR (Ceoc), DOT 407/412 standards. Founded in 1989 and has since grown into a dynamic company that operates globally and consists of eight specialised subsidiaries in the USA, The Netherlands, the Czech Republic, Saudi Arabia, Slovakia and participations in rental organizations that operate in the Netherlands and the United Kingdom. As a growing, innovative and reliable company, KOKS Group has gained an excellent reputation in the (petro)chemical sector and other industries as a vacuum truck builder.