- Marketleader in no-man-entry robots

- Game-changing cleaning method

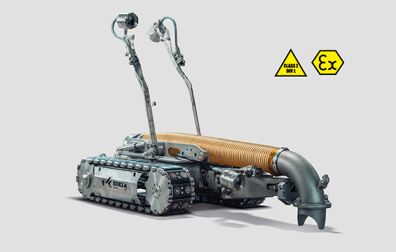

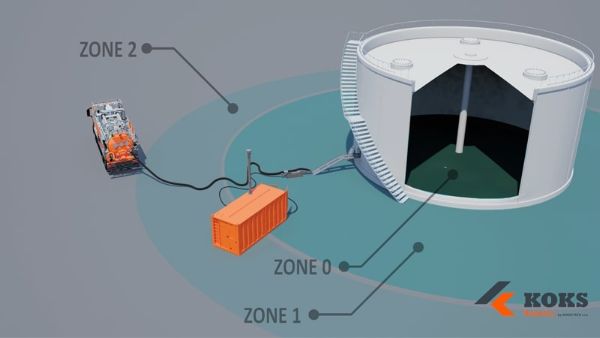

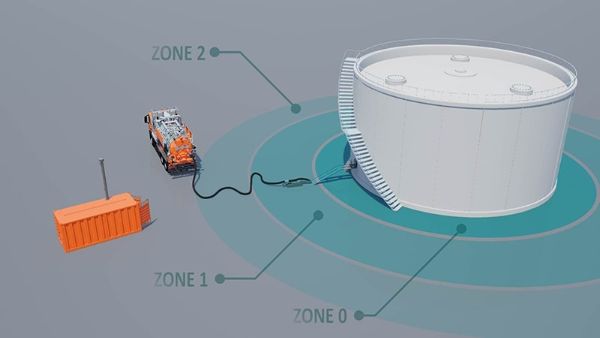

- ATEX zone 0 certified robots

Non-man entry cleaning robots for the refineries and tank farms

Refineries & Tank terminals

A refinery (in this case oil or petroleum) is an industrial process plant where crude oil is transformed and refined into more useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene, liquefied petroleum gas, jet fuel and fuel oils. Petrochemicals feed stock like ethylene and propylene can also be produced directly by cracking crude oil without the need of using refined products of crude oil such as naphtha.

Oil refineries are typically large, sprawling industrial complexes with extensive piping running throughout, carrying streams of fluids between large chemical processing units, such as distillation columns. In many ways, oil refineries use much of the technology, and can be thought of, as types of chemical plants.

An oil terminal (also known as tank farm or oil depot) is an industrial facility for the storage of oil, petroleum and petrochemical products, and from which these products are transported to end users or other storage facilities. An oil terminal typically has a variety of above or below ground tank storages.

Robots for refineries & tank terminals

What are the types of danger in the refineries & terminals for industrial cleaners?

The foremost danger on each oil & petroleum refinery and/or terminal are the gases of the products processed or stored. These gasses are often subjected to being explosive or poisonous. The first is in the European directives referred to as ATEX classified zones. The amount of risk determines whether the ATEX zones for gas or mist explosive risk are indicated with ATEX zone 0, 1 or 2.

Where to utilize a robot in the refineries & terminals industry?

The majority of the work where the robot is already utilized on refineries and tank terminals is to clean out the sediment of the tanks. This can be for periodic recertification of the tank or changing the product in the tank to avoid a chemical reaction. The robot is designed to enter through the 24 ‘’ / 600 mm manhole to start the cleaning procedure normally done by manual labour. The robot teams up with an ADR-certified vacuum truck to ensure a safe working environment for the small team in charge of cleaning the tank.

Applications

- Cleaning out tanks of sludges to avoid human entry of a dangerous ATEX Zone 0 classified zone.

- Robotic cleaning of the basins to remove oil residues, sands or other residue.

KOKS Robotics, formerly known as ADROC Tech s.r.o., is market leader and manufacturer of innovative no-man-entry tank cleaning robotics for ATEX zone 0. KOKS Robotics is part of the Dutch company KOKS Group an international manufacturer and supplier of vacuum trucks and heavy industrial cleaning equipment, built in accordance with the latest PED, ADR (Ceoc), DOT 407/412 standards. Founded in 1989 and has since grown into a dynamic company that operates globally and consists of eight specialised subsidiaries in the USA, The Netherlands, the Czech Republic, Saudi Arabia, Slovakia and participations in rental organizations that operate in the Netherlands and the United Kingdom. As a growing, innovative, healthy and reliable company, KOKS Group has gained an excellent reputation in the (petro)chemical sector and other industries as a vacuum truck builder.