- Marketleader in no-man-entry robots

- Game-changing cleaning method

- ATEX zone 0 certified robots

Robotic system for tank cleaning and storage tank maintenance

KOKS ESOT robotic system for tank maintenance

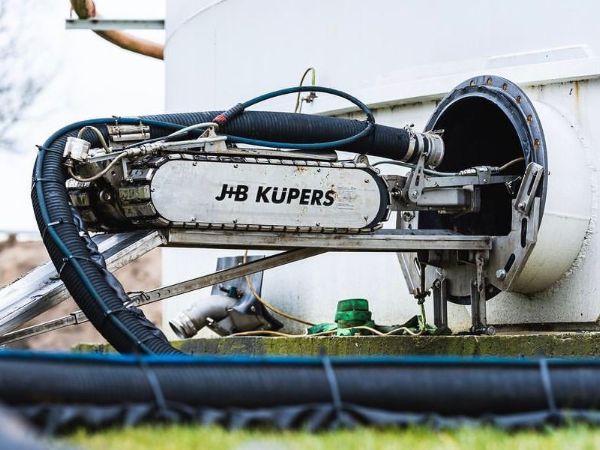

The KOKS ESOT-system is designed for heavy industrial applications and is suitable for no-man entry tank maintenance in order to eliminate the need for personnel to enter a hazardous environment. ESOT is the acronym for equipment set for oil tank cleaning. The ESOT-system is utilized in combination with a vacuum truck for discharging and transporting fluid and hazardous substances, such as liquids, sludge, fats, oils, fuels and chemicals. Specially developed for working with hazardous and contaminated substances, the robot is certified for ATEX (Ex) zone 0. The transportable, vented cabin (TVC) is available in a standard container, an ATEX (Ex) zone 1 and zone 2 version and built in accordance with all applicable safety standards.

Usage

The KOKS ESOT-system enables its user to clean the ATEX zone 0 without a human entry of the ATEX zone 0 itself. Commonly used for the cleaning of black and white oil storage tanks, the health, safety environment and quality improvements are undeniable.

Characteristics

The powerful patented, abrasive, magnet tracks of the ATEX certified robot enable this versatile system to move with ease through the contaminated tank. From the vented cabin every movement of the robot can be controlled and seen on a HD television screen. The robot, which is connected to the vacuum truck, will enable large quantities of (fluid) substances to be processed in a short time and then be transported in accordance with current ASME/ADR (CEOC) regulations. The user benefits from significant time savings and a huge reduction in cost.

Versions

The KOKS ESOT-robotic system can be fitted with various option kits that are appropriate for your needs and/or for industrial applications.

Benefits

- Reduction of cost.

- Undeniable improvement for health, safety, environment and cleaning quality.

- Easy control.

- Ergonomic.

- Built to the latest environmental and safety standards.

- First robot being certified for ATEX zone 0.

- No VOC in the ventilated cabin, providing safe conditions for the crew to operate without any need for additional protective gear.

- Patented TVC cabin for ATEX zone 1 or 2.

- Increase of operational efficiency.

- Maximum grip on the floor by patented, abrasive, magnetic tracks.

- Strong hydraulic power source.

- Heavy duty hydraulically operated arm, creating 2,000 Nm in any direction.

- Versatile robotic movements which enable it to move with ease through dense sludge.

- Complete robot made of the highest grade of stainless steel, AISI 316 grade; material no. 1.4404.

- Compact.

- Easy set up.

- Able to work continuously, 24/7.

Designed and certified for

- a 20 ft container, CSC certified.

- operation in ATEX zone 0, 1G, IIB, T4 (robot).

- international protection class IP66 (robotic system).

Robot

- Type: ADEX robot.

- Material: stainless steel AlSl 316 grade; material no. 1.4404.

- Certification: ATEX zone 0.

- Standards: EN 13463-1, EN13463-3, EN13463-5, EN13463-6, EN13463-8.

- Max. range: 100 m.

- Traction force: 3,000 N, measured on Fe plate, thickness 10 mm, covered in oil.

- Speed ATEX zone 0: 1-10 m/min.

- Wading depth: 250 mm.

- Ambient temperature: -10°C to 50°C.

- Tracks: 84 pieces, fully rubberized, anti-static NBR rubber, material material I 4165 LC, hardness up to 70 ShA..

- Arm motion: 35° in any direction.

- Arm force: 2,000 Nm.

Transportable, vented cabin (TVC)

- Basic TVC: standard sea container.

- Ambient/storage temperature: -20°C to 40°C/-20 to 50°C.

- Max. wind force: 6 Beaufort.

- Dimensions for transport (l x w x h): 6,058 x 2,591 x 2,438 mm (without suction chimney).

- Dimension at work (l x w x h): 6,058 x 2,438 x 6,910 mm (with suction chimney).

- Weight: approx. 7,500 kg (incl. robot and all accessories).

- Amount ventilated/conditioned rooms: 3/2.

- Supply voltage/rated current: 3~400 V, TN-S, 50 Hz/40 A without residual current circuit breaker.

- Max./average power consumption with ADEX robot: 11,5 / 7,5 kW.

- Directives/norms: EN 60079-0 +A11, EN 50381.

- DVR recording system: for 4 camera feeds, 1 TB storage.

- Control system: industrial computer enabling semiautomated cleaning program.

- Additional accessories: full HD TV screen, 1,080 px, 32” (80 cm). Air conditioning and ventilation unit. Sensors for door, overpressure, air flow, fire emergencies. Control panel for robot. Steel shutters to protect the windows during transport.

Hydraulic power pack

- Pressure: 70-100 bar.

- Max. power supply: 5 kW.

- Aggregate connection: 3x 400 V, 50 Hz.

- Directives: machinery directive 2006/42/EG, EN ISO 12100, EN ISO 614-1+A1, EN ISO 4413, EN 60204-1ED.2.

- Noise level: max. 80 dB(A).

KOKS Robotics is market leader and manufacturer of innovative no-man-entry tank cleaning robotics for ATEX zone 0. KOKS Robotics is part of the Dutch company KOKS Group an international manufacturer and supplier of vacuum trucks and heavy industrial cleaning equipment, built by the latest PED, ADR (Ceoc), DOT 407/412 standards. Founded in 1989 and has since grown into a dynamic company that operates globally and consists of eight specialized subsidiaries in the USA, The Netherlands, the Czech Republic, Saudi Arabia, Slovakia and participations in rental organizations that operate in the Netherlands and the United Kingdom. As a growing, innovative and reliable company, KOKS Group has gained an excellent reputation in the (petro)chemical sector and other industries as a vacuum truck builder.