- Marketleader in no-man-entry robots

- Game-changing cleaning method

- ATEX zone 0 certified robots

Robotic system for hazardous waste removal

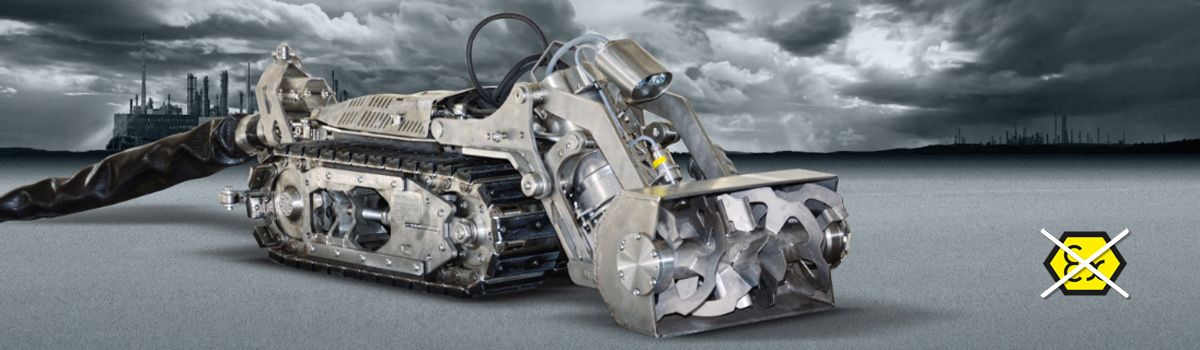

KOKS SAKAL no-man entry robot for hazardous waste cleaning

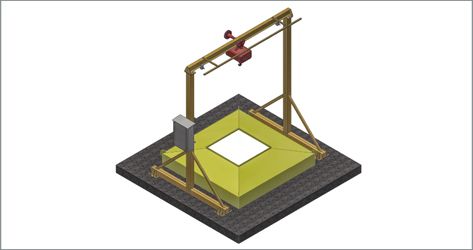

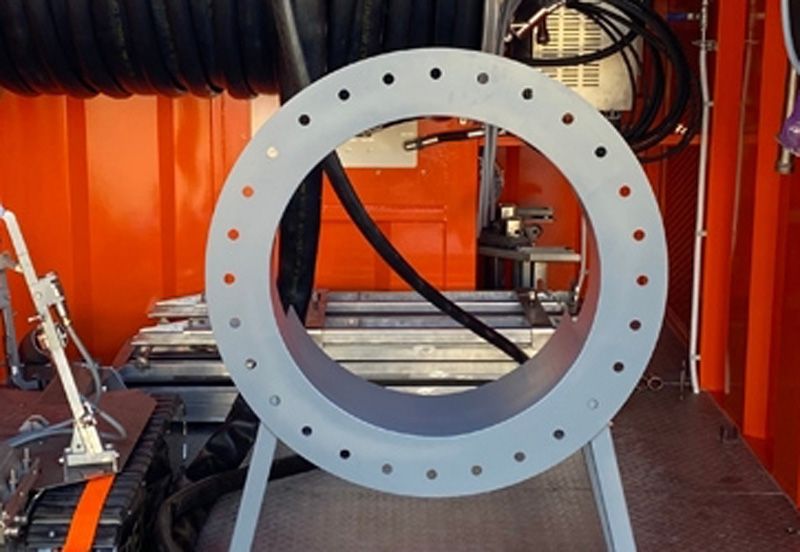

The KOKS SAKAL-system was originally designed for handling and removal of pollution from hazardous and contaminated storage and drain tanks at the site of nuclear power plants, where human access is necessarily restricted due to the radiation levels present. The SAKAL-system is designed for long-term use under severe conditions in stainless steel tanks and various other types of confined spaces in submerged conditions.

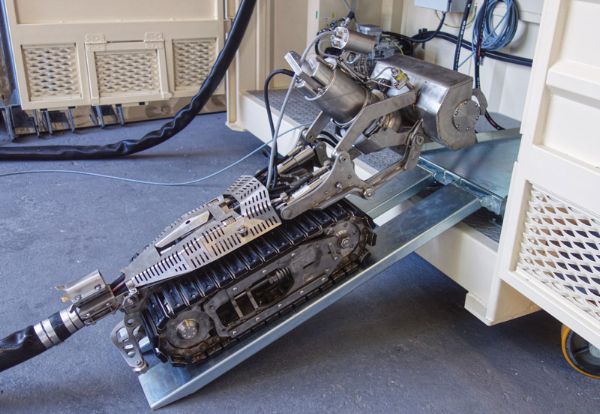

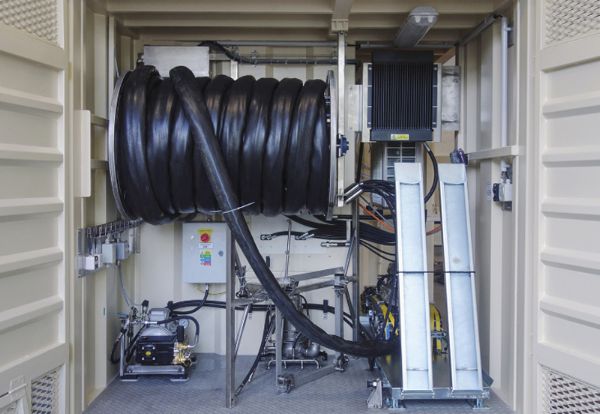

In addition, the KOKS SAKAL-system is a proven design for heavy and hazardous industrial applications and is suitable for cleaning areas such as underground tanks or collection basins with restricted human access. The system is equipped with a cabin for the operating personnel to act as an operating and control module on-site and can remain on-site as long as required for the job.

Usage

The KOKS SAKAL-system enables its users to clean irradiation-exposed areas with limited human access as well as general waste areas where human access is undesirable, such as sewage treatment plants. Used for cleaning during downtimes or even when nuclear power plants are operating, the improvements in quality, health, safety and the environment (QHSE) are undeniable.

In the decommissioning of old nuclear power plants, the system is ideal for difficult work such as removal of accumulated sewage sludge and debris that could not be removed during the life of the nuclear power plant. Of course, this is just a sampling of the wide variety of industries that the SAKAL-system can make safer by eliminating personnel from hazardous environments.

Characteristics

From the cabin, all movements of the robot are controlled by the operator. These can be followed on the HD screen via the onboard camera or via an external camera with an aerial view. The robot, which is connected to the vacuum truck, will enable large quantities of (fluid) substances to be processed in a short time and then be transported for decontamination and/or storage according to the customer's procedures. Instead of a vacuum truck, an onboard submersible pump can also be used to circulate the water for cleaning, waste separation and return to the tank.

Versions

The KOKS SAKAL-robotic system can be fitted with various option kits that are appropriate for your needs and industrial applications.

Benefits

- Designed to make decontamination easier.

- Dose rate meter for online monitoring.

- Selection of superstructures for different kinds of jobs.

- Undeniable improvement for quality, health, safety and environment (QHSE).

- Easy control.

- Ergonomic.

- Built to the latest environmental and safety standards.

- Greater operational efficiency.

- Powerful hydraulic power source.

- Manoeuvrable robot which can move through stiff sludge with ease.

- Complete robot made of stainless steel AISI 316 grade; material no. 1.4404.

- Compact.

- Easy set up.

- Able to work continuously, 24/7.

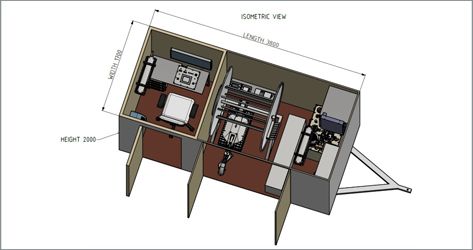

Transportable control cabine (TCC)

- Ambient/storage temperature: -15°C to 50°C.

- Type of operation: continuous, 24/7.

- Dimensions for transport (l x w x h): 6,058 x 2,438 x 2,591 mm

- Weight: approx. 7,000 kg (with robot and all accessories).

- Insulation: 50 mm of polystyrene.

- Amount ventilated/conditioned rooms: 3/2.

- Supply voltage/rated current: 3~400 V, TN-S, 50 Hz/40 A.

- Directives/standards: STN EN 33-2000-6, STN EN 33 1500, STN EN 62 305.

- DVR recording system: for 1 camera feed on the robot, 1 TB storage.

- Control system: industrial computer enabling semi-automated cleaning program.

- Additional accessories:

- full HD TV screen, 1,080 px, 32" (80 cm);

- air conditioning and ventilation unit;

- control panel for robot;

- steel shutters to protect the windows during transport;

- high pressure water attachment;

- hydraulic hose reel for storage and retraction.

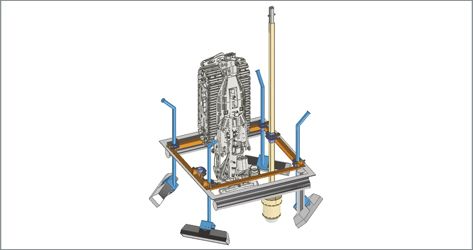

Robot

- Type: SAKAL-robot.

- Material: stainless steel AISI 316 grade; material no. 1.4404.

- Standards: STN EN 33-2000-6, STN EN 33 1500, STN EN 62 305.

- Standard range: 40 m.

- Traction force: 1,000 N.

- Wading depth: 20 m (watertight).

- Ambient temperature: -10°C to 50°C.

- Tracks: stainless steel, with full rubberized track plates.

- Rotary sludge disruptor: 32 Nm rotation power.

- Other features:

- suspension hooks to lower the system into the tank from above;

- designed for easier decontamination.

Hydraulic power pack

- Hydraulic power unit: 2 pumps connected in sequence.

- Pressure: 70-100 bar.

- Max. power supply: 5 kW

- Aggregate connection: 3x 400 V, 50 Hz

- Directives: machinery directive 2006/42/EG, EN ISO 12100, EN ISO 614-1+A1, EN ISO 4413, EN 60204-1ED.2.

- Noise level: max. 80 dB(A).

KOKS Robotics is market leader and manufacturer of innovative no-man-entry tank cleaning robotics for ATEX zone 0. KOKS Robotics is part of the Dutch company KOKS Group an international manufacturer and supplier of vacuum trucks and heavy industrial cleaning equipment, built by the latest PED, ADR (Ceoc), DOT 407/412 standards. Founded in 1989 and has since grown into a dynamic company that operates globally and consists of eight specialized subsidiaries in the USA, The Netherlands, the Czech Republic, Saudi Arabia, Slovakia and participations in rental organizations that operate in the Netherlands and the United Kingdom. As a growing, innovative and reliable company, KOKS Group has gained an excellent reputation in the (petro)chemical sector and other industries as a vacuum truck builder.